If you have owned your central HVAC system for any length of time, then you can probably pick out when changes in airflow or the sounds of your system occur. It could be uneven temperatures in areas throughout the house, or a general lack of consistent airflow, but the big sign most homeowners pay attention to is a higher monthly energy bill.

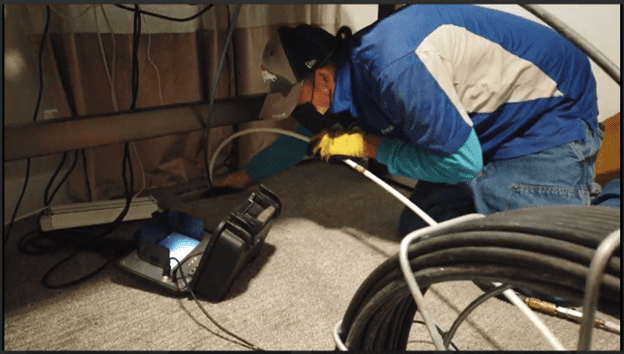

One reason for airflow issues is leaky ducts—cracks, gaps, tears and wear are not unusual in older ductwork. Sealing your ducts can prevent air leaks, therefore saving you money on energy bills and preventing your HVAC system from working harder than it should to cool or heat your house.

There are a few ways to seal ductwork, including using a silicone or acrylic duct sealant in Weber County, UT. Before diving into the silicone vs. acrylic sealant debate, let’s first review what they are.

Silicone sealant

Based on silicone polymers, silicone sealants cure and become a tough, flexible rubber that’s great for a variety of household and industrial applications. There are three main types of silicone sealant: acetoxy cure, alkoxy cure and oxide cure. A majority of interior applications take acetoxy cure, while the latter, neutral curing silicones are used for exterior applications because of their highly rated adhesion and weatherproofing properties. If you’re working with a surface that’s sensitive to acetic acid, choose a neutral curing silicone.

Acrylic sealant

Acrylic sealants are based on acrylic polymers. These sealants go by several other names, including decorator’s caulk, decorator’s acrylic and painter’s caulk. Even though acrylic sealants are traditionally used in interiors as an economical filler and sealant, some can be used in exteriors.

Difference between acrylic sealant and silicone sealant

It’s important to know the differences between silicone and acrylic sealants, as well as the advantages each bring to the table. With all the information in front of you, you’ll be able to compare these two sealant types to one another before deciding on the one to use for your project.

One advantage acrylic sealant has over silicone sealant is paintability. Most paints can be used on acrylic sealants, which is not the case with silicon sealants. However, if the sealant is for your ductwork, there’s no real need for paint. A downside to silicone is that it produces an unpleasant vinegar odor during curing, but there are also some odorless silicone options.

On the positive side, silicone sealants are more flexible and longer lasting than acrylic, and they do not have a volume shrinkage. Acrylic sealants have a major disadvantage in that they are water permeable. It’s advised that you not use acrylic in damp or humid places due to the risk of mold growth.

Feel free to contact the team at Fresh Ducts to learn more about acrylic and silicone duct sealant in Weber County, UT. With a proper duct sealant in place, you and your family will benefit from cool air in the summer and warm air in the winter. Call us today to get started!